Dolomite Powder

Dolomite Powder Specification

- Density

- 2.85 Gram per cubic centimeter(g/cm3)

- Water Absorption

- Negligible

- Usage & Applications

- Used in manufacturing of glass, ceramics, paints, detergents, rubber, water treatment, agriculture, and as refractory lining material.

- Hardness (%)

- 3.5 (Mohs scale)

- Application

- Glass, Paints, Ceramics, Rubber, Construction, Detergent, Agriculture, Water Treatment, Refractories

- Form

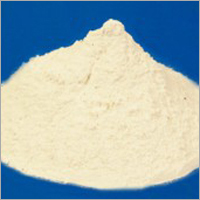

- Fine Powder

- Surface Finish

- Smooth, Fine Texture

- Melting Point

- 2570C

- Product Type

- Mineral Powder

- Types of Refractories

- Basic Refractories

- Shape

- Powder

- Porosity

- Low

- Dimensional Stability

- Excellent

- Strength

- High compressive strength

- Thermal Conductivity

- Low

- Color

- Pure White to Off White

Dolomite Powder Trade Information

- Minimum Order Quantity

- 1 Ton

- FOB Port

- Mundra Port

- Payment Terms

- Letter of Credit at Sight (Sight L/C), Cheque

- Delivery Time

- Days

- Sample Available

- Yes

- Sample Policy

- Free samples are available

- Packaging Details

- 25 Kg Bags 50 Kg Bags 1 Ton Bag

- Main Export Market(s)

- Eastern Europe, Middle East, Africa, Australia, South America, Western Europe, Asia, North America

About Dolomite Powder

Dolomite Powder

With firm commitment to quality, our organization is manufacturing, supplying and exporting high quality Dolomite Powder. The powder which we offer is processed by our experienced professionals, making sure the product does not contain any kind of impurities. Our team of quality controllers examine every batch on certain quality parameters to ensure flawless quality. The Dolomite Powder is mostly used as an ingredient for manufacturing paint, ceramics , rubber and many other products.

Other details:

Dolomite powder is available in white powder form. The various grades and their applications are:

GRADE |

FORM |

APPLICATIONS |

|

200 Mesh |

powder |

Paints, Ceramics, Rubber |

|

ASHA DL - 10 |

powder |

Paints |

|

ASHA DL - 20 |

powder |

Paints, Rubber |

|

ASHA DL - 40 |

powder |

Paints, Rubber |

|

ASHA DL - 70M |

powder |

Paints, Ceramics, Rubber |

Versatile Industrial Applications

Dolomite Powder is highly valued for its adaptability in industries like glass manufacturing, ceramics, rubber, water treatment, and paints. Its strength and purity ensure stable product integrity and superior performance, making it indispensable in modern manufacturing processes. The powders chemical composition and physical properties support its use as a refractory lining, construction aggregate, and agriculture supplement, establishing its role as a multi-industry essential.

Exceptional Material Qualities

Engineered for high performance, Dolomite Powder exhibits exceptional features, including low thermal conductivity, high compressive strength, and excellent dimensional stability. With a density of 2.85 g/cm and negligible water absorption, it sustains rigorous applications where reliability and efficiency are crucial. Its smooth, fine texture and stable chemical behavior contribute to superior results in both bulk and precision processes.

FAQs of Dolomite Powder:

Q: How is dolomite powder processed for industrial use?

A: Dolomite powder is produced by mining high-quality dolomite rocks, followed by crushing, grinding, and purification processes to achieve a fine, uniform powder. This ensures purity and consistency, matching specifications for various industrial applications.Q: What are the main benefits of using dolomite powder in manufacturing?

A: Dolomite powder offers high compressive strength, excellent dimensional stability, low thermal conductivity, and a smooth finish. These features enhance product durability in glass, ceramics, rubber, and refractory applications, while also improving efficiency in construction and agriculture.Q: Where is dolomite powder commonly used?

A: This versatile powder is extensively utilized in industries such as glass, ceramics, paints, construction, detergents, rubber, water treatment, agriculture, and as a basic refractory lining material, especially in India where it is both manufactured and exported.Q: When should dolomite powder be used as a refractory material?

A: Dolomite powder serves as a basic refractory material when high resistance to melting, thermal shock, or chemical attack is required. Its high melting point (2570C) and low porosity make it ideal for lining furnaces and kilns in steel and glass production.Q: What properties make dolomite powder suitable for water treatment?

A: Its negligible water absorption, purity, and stable chemistry allow dolomite powder to neutralize acidic water, assist in softening, and remove impurities, making it highly effective in water treatment facilities.Q: How does dolomite powder benefit agricultural applications?

A: Dolomite powder is used as a soil conditioner to provide essential calcium and magnesium, enhancing soil structure, neutralizing acidity, and improving nutrient absorption for better crop yield.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Minerals Products Category

Kaolin Clay

Minimum Order Quantity : 1 Ton

Shape : Powder

Color : White

Product Type : Minerals

Application : Industrial

Calcined Clay

Minimum Order Quantity : 1 Ton

Shape : Powder

Color : White

Product Type : Minerals

Application : Industrial

Send Inquiry

Send Inquiry